Aluminum Plate For Tanker Price

Potential buyers searching "Aluminum Plate For Tanker " usually want one thing: a quote they can trust. But tanker plate pricing isn't a single number—it's a mix of alloy, temper, thickness, width, inspection requirements, and how the material will be formed and welded.

Below are 5 hot questions commonly asked across Google/Quora-style forums, answered in a buyer-first way so you can compare offers without getting lost in supplier jargon.

1) What is the current Aluminum Plate for Tanker price per kg or per ton—and why do quotes vary so much?

A realistic quote is typically built from (A) metal value + (B) conversion cost + (C) extras + (D) logistics & risk. Two suppliers can quote very different prices even on the same alloy because their assumptions differ.

What usually drives variance:

Alloy and temper: 5083/5454/5754 are not priced like 1050/3003. Plate vs sheet also changes processing cost.

Thickness and width: wider and thicker plate often has lower yield in production and higher handling cost.

Certification & testing: EN 10204 3.1, MTC, ultrasonic testing, third-party inspection, or NDT documentation add cost.

Flatness/shape tolerance: tanker body panels may require tighter flatness for easier forming and fewer rejects.

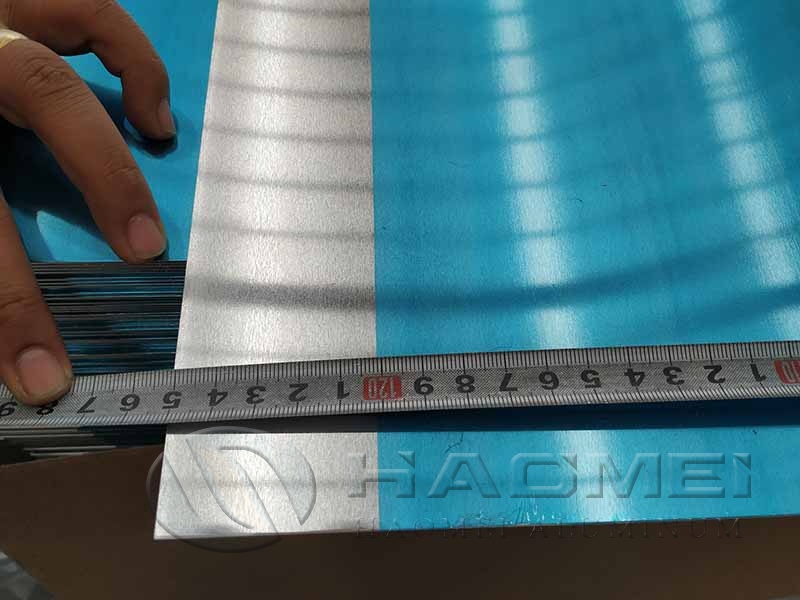

Surface/film: PVC coating, paper interleaf, or peelable film for cosmetic surfaces.

Market timing: aluminum price swings can move daily; many suppliers quote “valid 24–72 hours.”

Buyer tip: don't compare "per-ton" only. Compare the delivered cost per usable square meter after you confirm tolerances, coating, and test requirements.

Quick quote checklist (send this to suppliers)

| Item | What to specify | Why it matters for price |

|---|---|---|

| Alloy/Temper | e.g., 5083-H321, 5454-H32 | Strength, corrosion, weldability, availability |

| Dimensions | thickness × width × length | Yield, cutting loss, rolling limits |

| Quantity | total tons + per size | Mill run efficiency; impacts discounts |

| Standard | ASTM/EN/GB + tanker spec | Determines acceptance criteria |

| Testing | MTC, 3.1, UT, PMI | Adds inspection time and fees |

| Delivery terms | EXW/FOB/CIF + destination | Freight and insurance can be huge |

2) Which alloy is best for tanker bodies (fuel, chemical, water)—and how does that affect price?

Different tanker cargoes push you toward different alloys. Price changes because alloying elements (like magnesium) and plate route (hot-rolled vs cold-rolled) affect production cost.

Common tanker choices:

5083 (marine-grade): strong, excellent corrosion resistance, widely used for tank shells and heads. Often priced higher than 5052 due to performance and demand.

5454: popular for fuel and chemical tankers because of good resistance in certain service environments and good weld performance.

5052: cost-effective, good corrosion resistance; often used for general tanks and non-critical structures.

5754: used in transport tanks and body panels; good formability.

If your design requires higher strength-to-weight or better fatigue behavior, some builders consider specialized grades like Aluminum 5059 for demanding marine/transport structures—availability and minimum order can influence price.

Buyer tip: ask your fabricator what their forming/welding process is (rolling radius, head forming, weld procedure). A "cheaper" alloy can cost more if it cracks during forming or needs extra stiffeners.

3) What thickness of aluminum plate is used for tanker shells, end caps, and baffles and what does thickness do to price?

Thickness is one of the strongest price levers because it affects both material weight and manufacturing yield.

In real-world builds, thickness selection depends on:

Tank diameter and length

Design pressure/vacuum

Baffle spacing and reinforcement strategy

Regulatory codes and customer specs

How thickness changes price beyond weight:

Thicker plate may require hot-rolled plate routes and special leveling.

Wider thick plate can be harder to source in tight tolerances.

Forming thick heads can increase scrap risk; some buyers pay for better flatness/temper consistency to reduce rejects.

Rule of thumb for quoting: always request price as both $/kg and $/sheet (or $/plate) in your target sizes. A low $/kg can hide expensive cutting loss if your widths don't nest well.

4) How can I tell if a tanker aluminum plate quote is 'complete' (and not missing hidden costs)?

A quote is incomplete if it doesn't clearly state what you will receive and how it will be verified.

Must-have items on a complete quote:

Alloy, temper, and standard (ASTM B209, EN 485, etc.)

Dimensional tolerances (thickness, width, length; flatness if required)

Surface condition (mill finish, one-side film, both-side film)

Documentation (heat number traceability + MTC/3.1)

Packaging (export seaworthy, skid type, moisture protection)

Lead time and validity (when production starts, when price expires)

Delivery term (EXW/FOB/CIF) and destination port/city

Common "hidden cost" flags:

"Thickness tolerance: standard" (but no standard stated)

No mention of protective film, then later charged as an add-on

No clarification of plate vs sheet route (flatness and properties differ)

No mention of test reports, then charged for certification later

Buyer tip: request at least one sample MTC format before paying deposit so you can confirm fields like chemistry, mechanicals, and heat traceability.

5) How do I negotiate Aluminum Plate For Tanker Price without sacrificing quality?

Negotiation works best when you trade manufacturing convenience for better pricing—without weakening performance.

Practical levers that lower cost:

Standardize sizes: fewer unique widths/lengths = better nesting, less scrap.

Bundle thicknesses: mills prefer fewer gauge changes.

Allow realistic tolerance where possible: overly tight flatness drives cost.

Plan order timing: locking quantity early helps mills schedule efficiently.

Consider coil-to-sheet programs if your application allows (often more economical than discrete plate for some thickness ranges).

If you're also sourcing tread plate for walkways, fenders, or service platforms on the tanker, combining those items can sometimes reduce overall freight and packaging cost. For example, pairing shell plate with accessories like tanker aluminum plate components (when applicable to your catalog structure) can simplify procurement and improve shipment efficiency.

A simple "apples-to-apples" quote comparison table

Use this table to compare supplier offers side-by-side.

| Supplier | Alloy/Temper | Size (mm) | Qty | Standard/MTC | Film | Price Term | Lead Time | Notes |

|---|---|---|---|---|---|---|---|---|

| A | 5083-H321 | 6×2000×6000 | 20 t | EN + 3.1 | 1-side | CIF | 25 days | UT optional |

| B | 5454-H32 | 6×2000×6000 | 20 t | ASTM + MTC | none | FOB | 18 days | tighter flatness |

Original Source:https://www.aluminumtankerplate.com/a/aluminum-plate-for-tanker-price.html

Tags: Aluminum Plate For Tanker Price , tanker aluminum plate , 5052 tanker sheet , 5083 aluminum plate ,