Aluminium 5083

Aluminium 5083 for tank truck sheet: why buyers specify it

Aluminium 5083 is a non heat treatable Al Mg alloy widely selected for corrosive service and welded structures. For bulk buyers supplying tank truck builders, the value is practical: stable mechanical performance after welding, strong resistance in marine like or chemically exposed environments, and reliable availability in plate and sheet formats.

In tanker body fabrication, 5083 is commonly used for shells, heads, baffles, and stiffeners where weight reduction, corrosion resistance, and weld integrity matter. Compared with many general purpose alloys, it is known for good toughness and consistent properties in thicker gauges. It is also frequently specified to recognized standards such as EN AW 5083 and AA 5083.

Typical specifications buyers request

Below is a practical reference table used when quoting and aligning production to tank truck drawing requirements. Exact limits depend on the standard and the temper, so purchase orders should state standard, temper, thickness tolerance, and inspection requirements.

| Item | Common options for tank truck sheet and plate | Why it matters for fabrication |

|---|---|---|

| Alloy designation | AA 5083, EN AW 5083 | Ensures chemistry and performance consistency across lots |

| Temper | H111, H116, H321 | Balances forming, strength, and corrosion resistance |

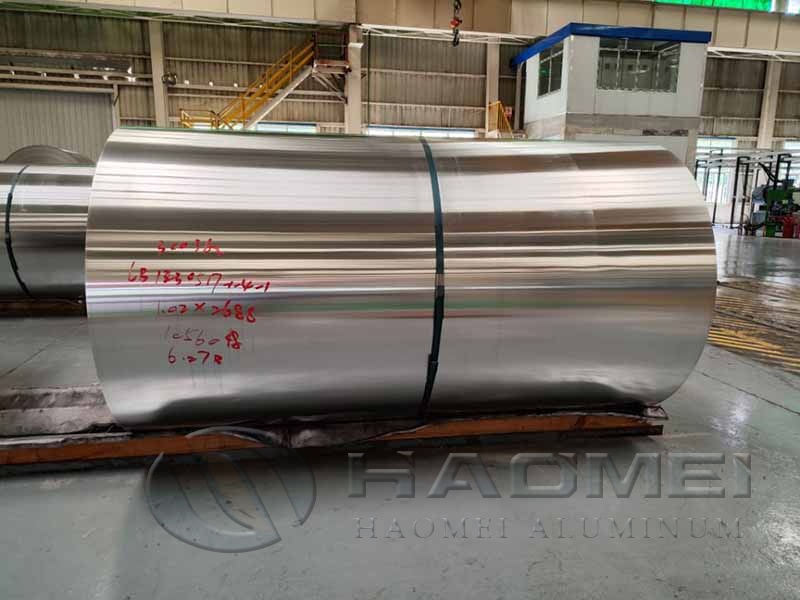

| Product form | Sheet, plate, coil cut to length | Impacts flatness, yield, and joining efficiency |

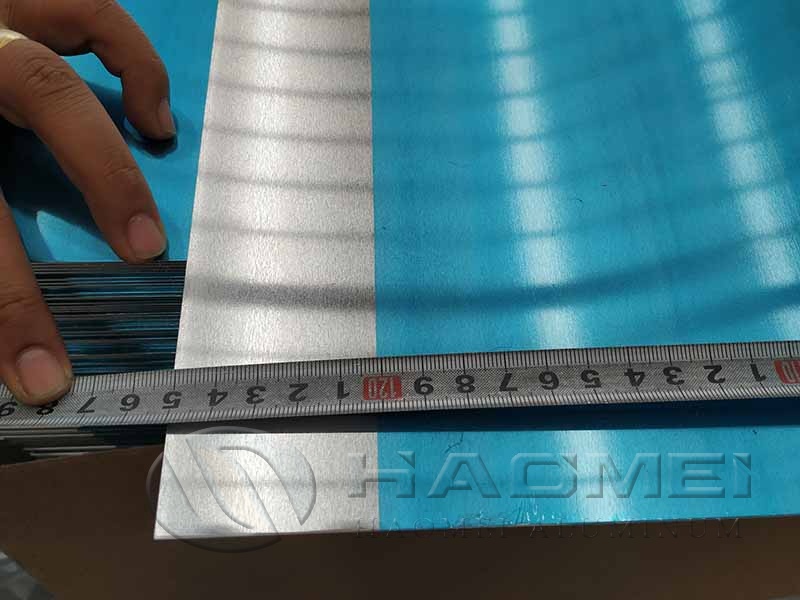

| Thickness range | Often 3.0 mm to 25 mm for tanker structures | Covers shell sections through formed heads and baffles |

| Width and length | Standard widths plus wide plate programs | Wider plate can reduce longitudinal weld seams |

| Surface | Mill finish, one side protective film on request | Protects cosmetic surfaces and reduces handling marks |

| Inspection | MTC, ultrasonic test by agreement, dimensional check | Helps control risk on critical welded assemblies |

Choosing temper: H111 vs H116 vs H321

H111 is often selected when buyers need more forming margin, such as complex head forming or tight radius bends. It is a lightly strain hardened condition and can be a good balance when fabrication shops prioritize formability.

H116 is commonly specified for improved corrosion performance in aggressive environments, especially where exposure to salt or humid coastal service is expected.

H321 is stabilized for strength retention and is also used in corrosive service, with good performance for welded structures.

For programs that require even higher strength or special performance in cryogenic or defense related service, some buyers evaluate Aluminum 5059 as an alternative, depending on design code and availability.

What bulk buyers care about: performance, yield, and supply stability

Corrosion resistance in real tanker service

5083 is recognized for strong resistance to seawater and industrial atmospheres, which translates well to tank truck use where road salts, humidity, and cargo residues can be persistent. For chemical transport, compatibility still depends on the specific media, cleaning regime, and lining requirements, so many OEMs treat alloy selection as part of a broader corrosion control plan.

Weldability and fabrication efficiency

5083 is generally considered highly weldable with common aluminum welding processes. Bulk purchasers typically focus on three shop floor outcomes:

Predictable weld quality and low rework rates.

Stable flatness and low residual stress to support roll forming and seam alignment.

Consistent mechanical properties across heats, especially for thicker plate used in heads or reinforcement.

To reduce scrap, many buyers specify tighter thickness tolerances, guaranteed minimum yield strength, and protective film on one side for visible exterior surfaces.

Sizing, cutting, and logistics

Large format plate and coil cut to length can improve material utilization. If your drawings allow wider plate, you may reduce weld length and labor hours on the shell. Typical procurement options include:

Standard sheet sizes for flexible stocking.

Wide plate programs for long shell courses.

Coil supply for automated blanking, where forming lines are optimized.

When you quote, it is helpful to define maximum unit weight, packaging standard, and whether your shop needs edge trimming or precision saw cut lengths.

Market trend notes for purchasing teams

Pricing for 5083 sheet and plate typically moves with primary aluminum ingot and regional rolling capacity. Freight and energy costs also influence delivered cost, especially for heavy plate. For stable supply, many bulk buyers split volumes between contract coverage and spot purchases, while keeping temper and standard consistent to reduce qualification risk.

Common tank truck applications for 5083 sheet and plate

The table below lists typical applications where 5083 is frequently chosen, with a buyer oriented view of what to specify.

| Tank truck component | Typical 5083 use | Specification tips |

|---|---|---|

| Shell courses | Rolled sections, longitudinal seams | Consider wide plate to reduce seams; control flatness |

| Heads | Dished or formed heads | Confirm forming requirements and temper choice |

| Baffles and bulkheads | Internal structures | Specify thickness tolerance to keep fit up consistent |

| Manway and nozzle areas | Reinforcement pads and rings | Align with welding procedure and inspection plan |

| Walkways and covers | Structural sheet parts | For traction surfaces, use dedicated tread products |

If your project also includes access platforms or service steps, pairing 5083 structural parts with Aluminum Tread Plate style materials can improve slip resistance and reduce maintenance complaints.

What to send in an RFQ to get faster, cleaner quotes

To avoid back and forth and protect lead time, include:

Alloy and temper: 5083 H111, H116, or H321.

Standard: ASTM, EN, or customer spec.

Thickness, width, length, quantity, and acceptable split sizes.

Flatness requirement and whether one side film is needed.

Test requirements: MTC, dimensional report, and any additional inspection.

Delivery terms, packing, and unloading constraints.

For tank truck builders and distributors, aluminium 5083 remains a practical choice because it supports strong weld performance, corrosion resistance, and efficient fabrication across a wide range of thicknesses and plate sizes.

Original Source:https://www.aluminumtankerplate.com/a/aluminium-5083.html

Tags: aluminium 5083 , 5083 H111 sheet ,